You might not realize it, but control limits are crucial in maintaining the quality and efficiency of your processes. They help you identify when things are going off track, allowing for timely interventions. Understanding how to establish and interpret these limits can significantly enhance your decision-making. But what happens when those limits are pushed? Exploring this can reveal insights that could transform your approach to process management.

Understanding Control Limits: A Fundamental Concept in Quality Control

While you mightn't realize it, control limits play a crucial role in quality control processes. These limits help you determine whether a process is stable or if it needs adjustments. When you set control limits, you establish boundaries for acceptable variation in your process. Anything outside these limits signals potential issues that require your attention.

Understanding control limits allows you to identify trends, shifts, or anomalies in your data. By monitoring these limits, you can differentiate between common cause variations and special cause variations. This knowledge is vital for implementing statistical analysis effectively, empowering you to make informed decisions, ensuring that your processes remain efficient and produce high-quality results. Ultimately, grasping control limits is essential for maintaining consistency and reliability in your operations.

The Importance of Control Limits in Process Management

Control limits are vital in process management because they provide a clear framework for evaluating performance and identifying areas for improvement. By setting these boundaries, you can quickly spot variations that may indicate issues in your processes.

This proactive approach helps you address problems before they escalate, ensuring that your operations run smoothly. When you monitor your processes against these limits, you gain valuable insights into trends and patterns, allowing for data-driven decision-making. Additionally, understanding control charts is essential as they are a key tool for monitoring process stability and quality.

Plus, control limits foster accountability among team members, as everyone understands the expectations. Ultimately, implementing control limits not only enhances efficiency but also boosts quality, leading to greater customer satisfaction and improved overall performance in your organization.

Types of Control Limits: Upper and Lower Boundaries

Understanding the types of control limits is essential for effectively managing processes, as they consist of upper and lower boundaries that define acceptable performance levels.

The upper control limit (UCL) indicates the maximum threshold a process can reach without signaling a potential issue. If your data points exceed this limit, it may suggest that the process is out of control.

On the other hand, the lower control limit (LCL) marks the minimum threshold, indicating the lowest acceptable performance level. If your data falls below this boundary, it could signal a need for investigation or corrective action.

How Control Limits Are Calculated

To effectively establish control limits, you'll need to analyze your process data and calculate the statistical parameters that define them.

Start by gathering a sufficient sample size to ensure accuracy. Calculate the mean (average) and standard deviation of your data set. The upper control limit (UCL) is typically set at the mean plus three times the standard deviation, while the lower control limit (LCL) is the mean minus three times the standard deviation.

This approach helps you capture natural variation in your process. Make sure to regularly update your calculations as new data comes in, ensuring your control limits remain relevant and accurate for ongoing process monitoring.

The Role of Control Charts in Monitoring Processes

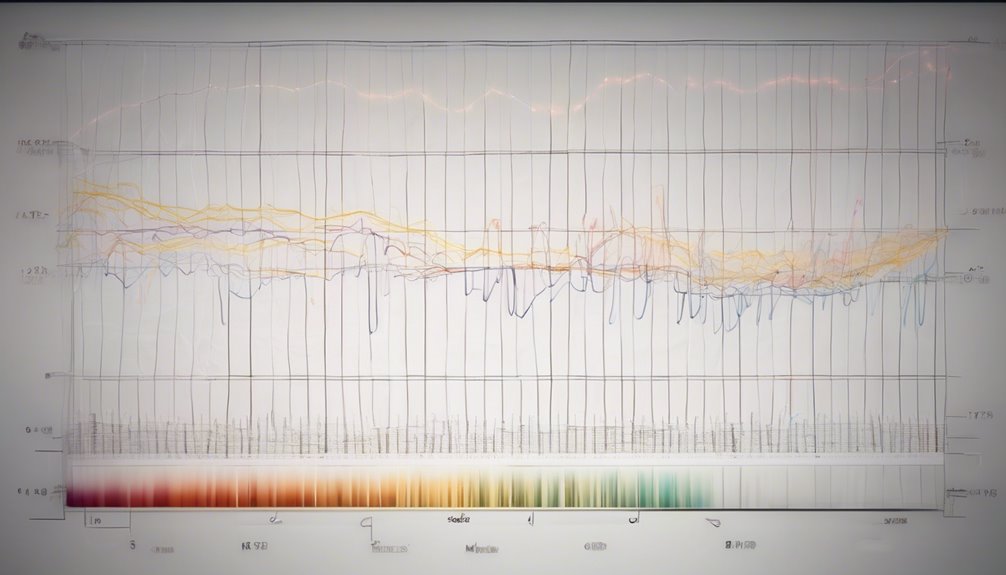

After calculating your control limits, the next step is to implement control charts, which serve as powerful tools for monitoring processes over time.

These charts visually display your data, allowing you to track performance and detect any deviations from expected behavior. By plotting your measurements against the control limits, you can easily identify trends or shifts that may indicate potential issues.

Regularly reviewing these charts helps you maintain process stability and make informed decisions quickly. You'll notice patterns and can respond proactively to any anomalies, ensuring that your processes remain efficient.

Ultimately, control charts empower you to enhance quality and minimize variations, leading to better overall performance in your operations. This method aligns with DMAIC's Control Phase, emphasizing the importance of sustaining improvements and monitoring key performance indicators.

Identifying Variations: Common Causes and Special Causes

While monitoring your control charts, it's crucial to differentiate between common causes and special causes of variation. Common causes are inherent to the process and result from regular fluctuations. They usually indicate a stable process but can lead to inefficiencies if not addressed.

On the other hand, special causes arise from specific, identifiable issues, such as equipment malfunctions or changes in materials. These variations signal a problem that needs immediate attention.

The Impact of Control Limits on Decision Making

Control limits play a pivotal role in your decision-making process, as they provide a framework for understanding process stability and performance.

When you establish control limits, you can quickly identify when a process is operating within acceptable ranges or when it's deviating from expected outcomes. This clarity allows you to make informed decisions, whether you need to investigate anomalies or implement corrective actions.

By monitoring these limits, you minimize risks and enhance efficiency, ensuring resources are allocated effectively. Additionally, you can foster a culture of continuous improvement, as regular analysis of control limits helps you refine processes over time.

Ultimately, understanding control limits empowers you to make timely, data-driven decisions that drive success.

Practical Applications of Control Limits in Different Industries

Understanding how control limits apply across various industries can significantly enhance operational efficiency and quality management.

In manufacturing, you can monitor production processes, ensuring outputs remain within specified limits, which minimizes defects.

In healthcare, control limits help in tracking patient vital signs, allowing for timely interventions.

In finance, you can use them to analyze transaction patterns, identifying anomalies that suggest fraud.

In the food industry, control limits ensure safety standards are upheld during production, maintaining quality and compliance.

In software development, they assist in measuring performance metrics, optimizing processes.

Challenges in Implementing Control Limits

Implementing control limits can be challenging, particularly when organizations lack a clear understanding of the underlying processes. You might struggle with data collection, as inconsistent or inaccurate data can lead to misleading control limits.

Additionally, if your team isn't trained properly, they'll find it tough to interpret the charts and understand their significance. Resistance to change is another hurdle; employees may be hesitant to adopt new practices, fearing it might disrupt their routine.

Lastly, maintaining control limits requires ongoing monitoring and adjustment, which can overwhelm your resources if not planned effectively. To overcome these challenges, it's essential to foster a culture of continuous improvement and invest in training and resources.

Best Practices for Effective Use of Control Limits

To make the most of control limits, you should start by ensuring that your data is accurate and consistently collected.

Regularly review your processes to identify any anomalies that could affect your results. When setting control limits, involve your team to foster understanding and buy-in.

Use historical data to establish realistic limits that reflect your process's natural variation. Monitor your control charts frequently, and don't hesitate to adjust limits as needed based on ongoing data analysis.

Encourage open communication about deviations and investigate their causes promptly. Finally, train your staff on the importance of control limits to create a culture of quality and continuous improvement.

Conclusion

In summary, control limits are vital for maintaining quality and stability in any process. By understanding and applying Upper and Lower Control Limits, you can effectively monitor performance and swiftly address anomalies. Remember, using control charts can enhance your decision-making and drive improvements in efficiency across various industries. Embrace best practices to overcome challenges and ensure you're leveraging control limits to their fullest potential for optimal results.