When it comes to enhancing process efficiency, Six Sigma tools play a pivotal role. You might find that utilizing tools like the Fishbone Diagram or Control Charts can significantly streamline your operations. These tools not only help identify issues but also prioritize them effectively. As you explore their practical applications, you'll see how each tool contributes to continuous improvement in ways you might not expect. What's next on your journey to mastering these techniques?

What Is Six Sigma?

Six Sigma is a data-driven methodology aimed at improving processes and reducing defects. You'll find it's about identifying and eliminating the causes of errors while enhancing overall quality.

By using statistical tools and techniques, you can measure process performance and uncover areas needing improvement. Six Sigma emphasizes the importance of understanding customer needs, ensuring that your processes align with those expectations.

It encourages a culture of continuous improvement, where teams work collaboratively to solve problems and implement solutions effectively. You'll notice that its principles can be applied across various industries, from manufacturing to services.

Ultimately, Six Sigma isn't just about achieving goals; it's about fostering an environment of excellence and accountability in everything you do. This approach aligns with the DMAIC methodology that provides a structured framework for problem-solving and process improvement.

The DMAIC Framework

The DMAIC framework is a powerful tool in the Six Sigma methodology, consisting of five key phases: Define, Measure, Analyze, Improve, and Control.

In the Define phase, you pinpoint the problem and set clear project goals. Next, during Measure, you gather data to understand the current process performance.

The Analyze phase helps you identify root causes of issues, enabling you to focus on what truly matters. Once you've identified these causes, the Improve phase allows you to develop solutions and implement changes to enhance performance.

Finally, in Control, you establish monitoring systems to ensure the improvements are sustained over time. This structured approach not only drives continuous improvement but also enhances overall organizational efficiency.

Process Mapping

Process mapping is an essential technique that visualizes the steps involved in a process, helping you identify inefficiencies and areas for improvement.

By creating a clear map, you can pinpoint where delays occur and where resources are wasted. Start by listing each step, from the beginning to the end, and include decision points. This will allow you to see the flow of tasks and interactions.

Use symbols like rectangles for tasks and diamonds for decisions to make your map easy to understand. Once you've mapped out the process, analyze it to find bottlenecks or redundancies. Engaging your team in this exercise can also generate valuable insights and foster collaboration, ultimately leading to a more streamlined operation. Additionally, applying control measures will help maintain the improvements achieved through this mapping process.

Fishbone Diagram

After mapping out the steps in your process, you might want to explore the Fishbone Diagram, also known as the Ishikawa or cause-and-effect diagram.

This tool helps you identify potential causes of a problem by visually organizing them into categories. Start by placing the main issue at the head of the fish, then draw the spine and add branches for each category, such as people, processes, materials, or environment.

As you brainstorm possible causes, involve your team to gather diverse insights. This collaborative approach ensures you don't overlook any factors.

Once you've identified the root causes, you can address them systematically, leading to effective solutions and improved outcomes in your process.

Control Charts

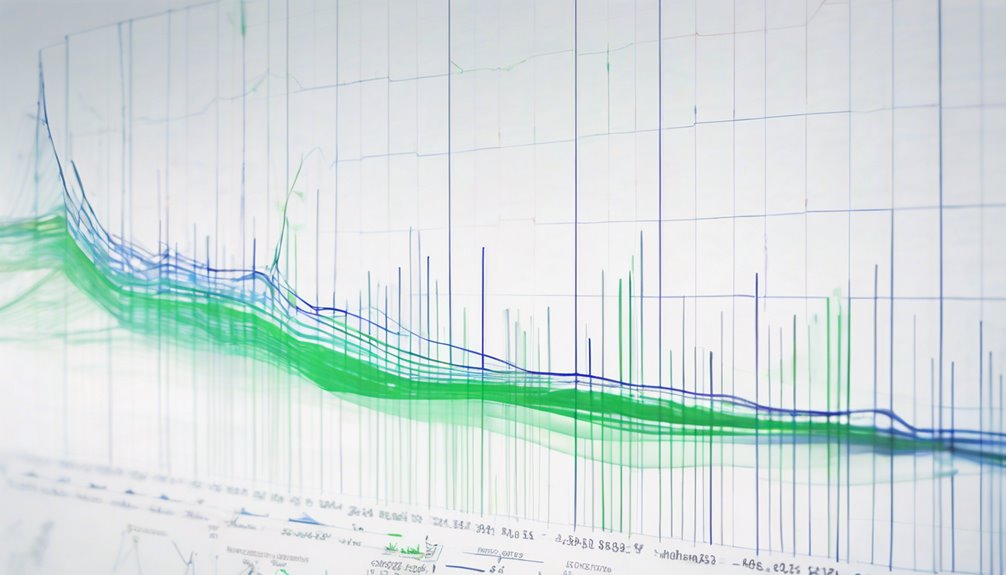

Control charts are essential tools in quality management that help you monitor process stability over time. By plotting data points in a time-ordered sequence, you can visually assess variations and identify trends.

You'll use control limits to distinguish between common and special cause variations, allowing you to pinpoint potential issues before they escalate. When a data point falls outside the control limits, it signals that something in the process may need your attention.

Regularly reviewing these charts keeps you proactive, ensuring that your processes remain within desired specifications. Utilizing control charts not only aids in maintaining quality but also fosters continuous improvement, empowering you to make informed decisions and optimize your operations. Moreover, effective Root Cause Analysis can be integrated with control charts to further enhance problem identification and resolution.

Pareto Analysis

When you want to focus your efforts on the most significant issues affecting your processes, Pareto Analysis is an invaluable tool. This technique helps you identify the vital few factors that contribute to the majority of problems.

By applying the 80/20 rule, you'll see that roughly 80% of your issues stem from 20% of the causes. Start by collecting data on the problems you face, then categorize and rank them by frequency or impact.

Once you've created your Pareto chart, you'll visualize which issues need immediate attention. With this clear focus, you can prioritize your improvement efforts, allocate resources more effectively, and ultimately enhance your process performance.

Incorporating data-driven decision-making into your analysis empowers you to make informed, strategic decisions for impactful change.

Histogram

A histogram is a powerful visual tool that helps you understand the distribution of data within a dataset. By organizing your data into bins, you can easily identify patterns, trends, and outliers.

When you create a histogram, you plot the frequency of data points on the vertical axis and the range of values on the horizontal axis. This allows you to see how often different values occur. You can quickly spot whether your data is skewed, evenly distributed, or has multiple peaks.

Histograms also assist in identifying potential areas for improvement in your processes. So, if you want to gain insights from your data, a histogram is an excellent choice that provides clarity and facilitates informed decision-making.

Voice of the Customer (VoC)

Understanding the Voice of the Customer (VoC) is crucial for delivering products and services that truly meet customer needs. By actively gathering feedback through surveys, interviews, and focus groups, you can identify what your customers value most.

This insight helps you prioritize improvements and tailor offerings to enhance satisfaction. It's important to analyze this data regularly, ensuring you're responsive to changing preferences.

Incorporating VoC into your processes not only strengthens customer loyalty but also drives innovation. Remember, when you listen to your customers, you're more likely to exceed their expectations.

Embrace this approach, and you'll create a culture focused on continuous improvement that directly aligns with what your customers want and need. Additionally, leveraging Kaizen principles in your improvement strategies can significantly enhance your responsiveness to customer feedback.

Conclusion

Incorporating Six Sigma tools into your processes can significantly enhance efficiency and quality. By leveraging techniques like the Fishbone Diagram, Control Charts, and Pareto Analysis, you can identify and eliminate defects effectively. Plus, using Histograms and gathering the Voice of the Customer ensures that your efforts align with customer needs. Embrace these tools to foster a culture of continuous improvement, boost performance, and ultimately deliver better results for your organization. Start your Six Sigma journey today!