Standardized work is crucial for enhancing efficiency in any manufacturing environment. By establishing consistent methods for performing tasks, you can significantly reduce errors and variability. This approach not only streamlines processes but also simplifies training for new team members. As you explore the principles and benefits of standardized work, you might find surprising insights that could transform your operations. What challenges might you face when trying to implement these practices effectively?

Understanding Standardized Work

When you think about improving efficiency in your workplace, understanding standardized work is essential. This approach involves creating a consistent method for performing tasks, ensuring everyone knows their roles and responsibilities.

By documenting best practices, you'll reduce variability and increase quality across your team. Standardized work isn't about rigidity; it's about flexibility within a framework. It allows you to identify inefficiencies and make adjustments based on real data.

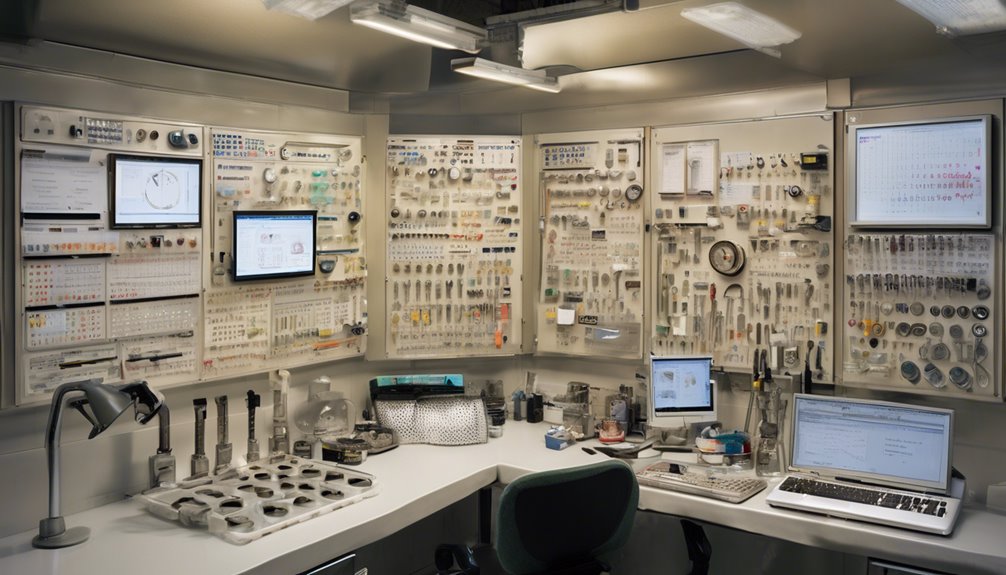

Engaging your team in this process fosters collaboration and ownership, making them more likely to embrace changes. By utilizing visual aids and clear instructions, you can streamline operations, reduce errors, and enhance productivity.

Ultimately, grasping standardized work equips you with the tools to create a more effective and efficient workplace. Implementing this approach aligns with the principles of continuous improvement, which is crucial for sustained organizational success.

The Importance of Standardized Work in Lean Manufacturing

Standardized work plays a pivotal role in lean manufacturing, acting as the backbone of efficiency and quality. By establishing clear guidelines for tasks, you ensure that every worker knows exactly what to do, reducing variability and errors.

This consistency not only boosts productivity but also enhances the overall quality of your products. When everyone follows the same procedures, you can easily identify areas for improvement and eliminate waste.

Plus, it empowers your team to take ownership of their work, fostering a culture of continuous improvement. Standardized work also facilitates training new employees, helping them become effective contributors more quickly.

Ultimately, embracing standardized work helps you achieve operational excellence and maintain a competitive edge in the market. Additionally, Lean Six Sigma methodologies provide a framework for integrating standardized work with continuous improvement efforts.

Key Principles of Standardized Work

Three key principles underpin effective standardized work, ensuring that processes are efficient and consistent.

First, focus on defining the best practices for each task. This involves observing the current methods and identifying the most effective steps.

Second, ensure that everyone is trained on these standardized procedures. When your team understands the processes, they can perform consistently and reduce errors.

Lastly, promote continuous improvement. Regularly review and refine your standardized work based on feedback and performance metrics. This helps you adapt to changes and maintain efficiency. Additionally, incorporating 5S principles can enhance the effectiveness of standardized work by promoting organization and reducing waste.

Benefits of Implementing Standardized Work

Implementing standardized work brings numerous advantages that can significantly enhance your operations.

First, it boosts efficiency by reducing variation in processes, allowing you to achieve consistent output. You'll find that your team can complete tasks quicker and with fewer errors, leading to improved quality.

Standardized work also promotes safety by establishing clear procedures, minimizing the risk of accidents.

Furthermore, it fosters a culture of continuous improvement, as employees can identify inefficiencies more easily when there's a clear baseline.

Training new team members becomes simpler, too, since standardized processes provide a clear framework to follow. Additionally, it aligns with the principles of continuous improvement, ensuring that your organization consistently seeks ways to enhance processes and customer value.

Steps to Develop Standardized Work Procedures

To fully realize the benefits of standardized work, it's important to develop effective procedures that everyone can follow.

Start by identifying the key tasks in your workflow. Observe how employees perform these tasks and gather input from them to understand their perspectives.

Next, document each step clearly, ensuring that it's easy to understand and accessible. Use visuals or flowcharts if necessary to enhance comprehension.

After drafting the procedures, test them out in a real-world scenario and gather feedback. Make any necessary adjustments based on this input.

Finally, train your team on the new procedures and encourage adherence. Regularly review and update these procedures to keep them relevant and effective, ensuring continuous improvement in your processes. Incorporating data-driven decision-making can further enhance the effectiveness of your standardized work procedures.

Challenges in Standardizing Work Processes

While standardizing work processes can drive efficiency and consistency, various challenges often arise that can hinder this goal. One major hurdle is resistance from employees who may feel their expertise is undervalued.

You might also encounter difficulties in documenting existing processes accurately, leading to confusion and inconsistencies. Additionally, the dynamic nature of work environments can make it tough to maintain updated standards.

Training staff effectively on new procedures is another challenge; without proper training, you risk losing the benefits of standardization.

Finally, measuring compliance and performance consistently is crucial but can be daunting. Addressing these challenges proactively is essential to successfully implement standardized work processes and ultimately achieve your efficiency and quality goals.

Case Studies: Successful Implementation of Standardized Work

Overcoming the challenges of standardizing work processes can lead to remarkable improvements in efficiency and quality.

For instance, a manufacturing company implemented standardized work procedures for assembly lines. By documenting each step and training employees, they reduced errors by 30% and increased output by 20%.

Similarly, a healthcare facility standardized patient intake procedures, which streamlined the process and improved patient satisfaction ratings significantly.

Another case involved a tech firm that adopted standardized workflows for software development. This approach cut project delivery times by 25% and enhanced team collaboration.

These examples demonstrate that when you embrace standardized work, you not only solve existing issues but also create a solid foundation for continued success and growth in your organization. Additionally, the use of data-driven decision-making in standardizing processes can further enhance operational effectiveness and customer satisfaction.

Fostering a Culture of Continuous Improvement Through Standardized Work

Embracing a culture of continuous improvement is essential for organizations aiming to thrive in today's competitive landscape. By implementing standardized work, you create a foundation for ongoing enhancement.

Standardized work ensures everyone follows best practices, reducing variability and increasing efficiency. When you encourage team members to suggest improvements, you empower them to take ownership of their processes.

Regularly reviewing and adjusting these standards keeps your organization adaptable and responsive to change. Celebrate small wins and recognize contributions to foster engagement and motivation.

Additionally, providing training and resources helps maintain focus on improvement initiatives. By integrating standardized work with a continuous improvement mindset, you not only boost productivity but also cultivate an environment where innovation thrives. Utilizing data-driven strategies is critical to enhancing efficiency and reducing variation in your processes.

Conclusion

In conclusion, adopting standardized work can transform your organization by enhancing efficiency and product quality. By defining best practices and training your team, you'll minimize errors and variability while fostering a culture of continuous improvement. Embracing this structured approach not only simplifies onboarding but also empowers your workforce to innovate and adapt. As you implement standardized work, you're setting the stage for lasting success and a safer, more productive workplace. Take the first step today!