In a world where efficiency and quality are not just goals but prerequisites for success, the concept of Six Sigma stands tall as a beacon of excellence in business processes and manufacturing.

Among its many levels of mastery, the Six Sigma Yellow Belt emerges as a fundamental yet profound stepping stone, offering insights into lean manufacturing and a framework for problem-solving that transcends traditional boundaries.

We will explore the intricacies of Six Sigma certification, particularly the Yellow Belt, unearthing its significance in the corporate world and beyond.

Read more about Six Sigma Yellow Belt

Here, we explore how this certification fits within the larger Six Sigma training spectrum, from the White Belt to the coveted Master Black Belt. By dissecting the principles of Define, Measure, Analyze, Improve, and Control (DMAIC), we reveal how the Yellow Belt serves as a certification and a transformative tool for improving product quality and streamlining business processes.

Whether you’re a professional seeking certified Six Sigma status or a company aiming for corporate training excellence, understanding the Lean Six Sigma Yellow Belt – its tools, methods, and implications – is paramount in today’s relentless pursuit of perfection.

More Things To Know About Six Sigma Yellow Belt

Understanding Six Sigma

When you want to understand Six Sigma, it’s important to know that it’s a global sensation, a methodology used to improve processes and reduce defects. Six Sigma is divided into different levels, or belt levels, to indicate the level of knowledge and expertise in the methodology.

One of these belt levels is the Six Sigma Yellow Belt. The Yellow Belt level is typically the entry-level certification in Six Sigma and provides a basic understanding of the methodology. As a Yellow Belt, you’ll learn the fundamental concepts of Six Sigma and gain the skills to support improvement projects within your organization.

While not as advanced as the higher belt levels, the Yellow Belt certification is a valuable starting point for individuals looking to contribute to process improvement initiatives and become more involved in Six Sigma projects.

History and Evolution of Six Sigma

Six Sigma’s historical heartbreak and hundred years of historical evolution can be understood by examining its origins and development.

Six Sigma, with its focus on process improvement and reducing defects, was first developed by Motorola in the 1980s. It gained widespread recognition and popularity when General Electric (GE) implemented it as a business strategy in the mid-1990s under the leadership of Jack Welch.

Since then, Six Sigma has been adopted by numerous organizations across various industries, leading to its evolution and refinement. This continuous improvement methodology has evolved from its initial focus on quality control to a broader application in areas such as customer satisfaction, cost reduction, and overall business performance.

The principles of Six Sigma, such as DMAIC, have been instrumental in driving organizational success and achieving measurable results. As a Yellow Belt in Six Sigma, you’ll gain a foundational understanding of these principles and their historical significance.

In industries such as the original Broadway productions, Six Sigma principles have been adapted to enhance efficiency in production processes, ensuring high-quality performances and optimal resource utilization.

Principles of Six Sigma

The principles of Six Sigma revolve around the idea of reducing variations and defects in processes to achieve improved quality and performance.

This is achieved through a systematic approach that involves defining, measuring, analyzing, improving, and controlling processes.

By applying statistical tools and techniques, Six Sigma aims to minimize process variation and bring it within acceptable limits.

The ultimate goal of Six Sigma is to meet customer requirements and achieve operational excellence.

Understanding these principles is essential for successfully implementing Six Sigma methodologies and driving positive change within your organization’s center for the performing arts.

Six Sigma Yellow Belt: An Overview

An individual holding a Six Sigma Yellow Belt is responsible for assisting with process improvement projects and supporting the implementation of Six Sigma methodologies. The Six Sigma Yellow Belt certification is the entry-level certification in the Six Sigma methodology. It provides individuals with a basic understanding of the principles and tools used in Six Sigma projects.

A Six Sigma Yellow Belt is trained to identify and analyze process problems, gather data, and assist Black Belts and Green Belts in implementing improvement initiatives. They play a vital role in supporting the Six Sigma team by participating in meetings, collecting data, and assisting in the implementation of improvement strategies.

While not leading projects themselves, Six Sigma Yellow Belts are an essential part of the Six Sigma team, contributing to the overall success of process improvement initiatives.

Role and Responsibilities of a Yellow Belt

As a Six Sigma Yellow Belt, your role and responsibilities revolve around supporting process improvement projects and implementing Six Sigma methodologies.

You play a crucial role in the success of Six Sigma initiatives within your organization. Your primary responsibility is to assist Green Belts and Black Belts in collecting and analyzing data to identify areas for improvement.

You’ll also be involved in documenting processes, conducting data analysis, and participating in improvement projects.

As a Yellow Belt, you’ll collaborate with cross-functional teams to implement process changes and monitor their effectiveness.

Your role is essential in ensuring the smooth implementation of Six Sigma strategies and achieving the desired outcomes.

Importance of Yellow Belt in Six Sigma Hierarchy

The Yellow Belt holds a significant role in the Six Sigma hierarchy, contributing to the success of process improvement initiatives and ensuring the effective implementation of Six Sigma methodologies.

As a Yellow Belt, you play a crucial role in supporting the project team by collecting and analyzing data, assisting in problem-solving efforts, and implementing process improvements.

Your understanding of the Six Sigma principles and tools allows you to actively participate in projects, helping to identify areas for improvement and contributing to the overall success of the organization.

Your knowledge and skills as a Yellow Belt make you a valuable asset in building a culture of continuous improvement within the organization.

Six Sigma Yellow Belt Certification

First, it’s important to understand the significance of obtaining this certification in your professional journey.

Next, you’ll want to familiarize yourself with the certification process, including the eligibility criteria and the steps you need to take to become certified.

Lastly, you should be aware of the exam pattern and syllabus to effectively prepare for the certification exam.

Importance of Certification

When pursuing a Six Sigma Yellow Belt Certification, it’s essential to understand the significance of obtaining this certification. Being a certified yellow belt demonstrates your understanding of the fundamental principles and practices of Six Sigma. It validates your ability to contribute to process improvement projects within an organization.

This certification not only enhances your knowledge and skills in process improvement but also boosts your professional credibility. It sets you apart from others by showcasing your commitment to quality and efficiency. As a certified yellow belt, you become a valuable asset to any organization, as you possess the necessary problem-solving and data analysis skills to identify and address process inefficiencies.

This certification opens up opportunities for career advancement, as many organizations value individuals with Six Sigma knowledge and certification. So, investing in a Six Sigma Yellow Belt Certification is a wise decision that can accelerate your professional growth and success.

Certification Process

To obtain a Six Sigma Yellow Belt Certification, you need to follow a specific certification process that will validate your understanding and skills in process improvement.

The certification process for a Six Sigma Yellow Belt involves several steps. First, you must complete a training program that covers the key concepts and tools of Six Sigma methodology. This training can be done online or in-person and typically lasts for a few days.

After completing the training, you’ll be required to pass an exam to demonstrate your knowledge and understanding of the Six Sigma principles. Once you pass the exam, you’ll receive your yellow belt certificate, which serves as proof of your expertise in process improvement.

This certification can enhance your career prospects and open up new opportunities for growth and advancement.

In industries such as cast recordings, having a Six Sigma Yellow Belt Certification can signify your commitment to quality and efficiency in the production process, potentially leading to increased credibility and recognition within the field.

The achievement of this certification often leads to a sense of euphoric celebration among individuals who have worked hard to attain it, marking a significant milestone in their professional development.

Eligibility Criteria for Yellow Belt Certification

Are you wondering what the eligibility criteria are for obtaining a Yellow Belt Certification in Six Sigma? Well, you’re in the right place! To ensure that individuals have the necessary skills and knowledge to be successful in the Six Sigma Yellow Belt Certification, there are certain requirements that must be met. Take a look at the table below to see the eligibility criteria:

| Eligibility Criteria |

|---|

| ———————- |

| Completion of a Six Sigma Yellow Belt training program |

| Understanding of basic statistical concepts |

| Familiarity with process improvement methodologies |

| Ability to work well in a team environment |

Exam Pattern and Syllabus

The exam pattern for the Six Sigma Yellow Belt consists of multiple-choice questions, typically ranging from 40 to 60 questions. The duration of the exam is usually around 1 to 2 hours.

The syllabus covers the fundamental concepts and methodologies of Six Sigma, including the DMAIC approach, process mapping, data collection and analysis, and basic statistical tools. It includes topics such as process capability, root cause analysis, and lean principles.

To excel in the exam, it’s essential to have a thorough understanding of these concepts and their applications in real-world scenarios. Studying the recommended reference materials and taking practice exams can greatly enhance your chances of passing the Six Sigma Yellow Belt Certification.

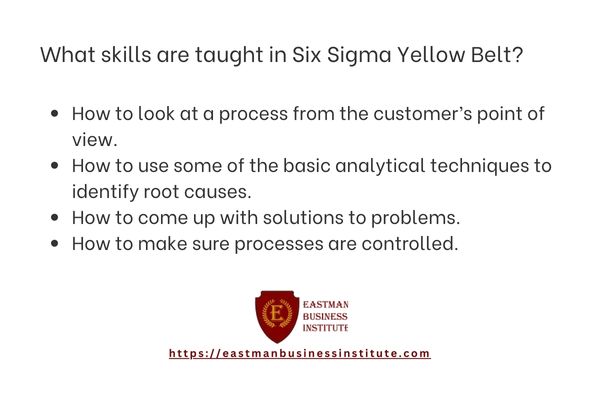

Skills Required for a Six Sigma Yellow Belt

When pursuing a Six Sigma Yellow Belt certification, there are several essential skills you should possess, even when involved in productions like Six on Broadway.

Analytical skills will enable you to gather and interpret data effectively, while problem-solving skills will help you identify and address issues within a process.

Teamwork skills are crucial for collaborating with others, including the tour cast, and communication skills are necessary for conveying information clearly.

These skills won’t only enhance your performance as a Yellow Belt professional but also contribute to the overall success of your projects.

Analytical Skills

As a Six Sigma Yellow Belt, you’ll need to possess strong analytical skills in order to effectively identify and analyze data for process improvement. Analytical skills are crucial for problem-solving and decision-making in a Six Sigma project. You’ll be expected to analyze data to identify trends, patterns, and root causes of problems.

This involves using statistical analysis techniques to interpret data and draw meaningful conclusions. You’ll also need to have the ability to think critically and logically, as well as apply problem-solving methodologies to address process issues. Your analytical skills will help you in designing experiments, measuring process performance, and making data-driven recommendations for improvement.

Problem-Solving Skills

Developing strong problem-solving skills is essential for a Six Sigma Yellow Belt. It allows you to effectively address and resolve process issues identified through your analytical analysis.

As a Six Sigma Yellow Belt, your role is to support the improvement initiatives within your organization. You’ll be responsible for identifying and solving problems to improve process performance.

By honing your problem-solving skills, you’ll become adept at identifying the root causes of issues, analyzing data, and implementing effective solutions.

Your certification as a Six Sigma Yellow Belt demonstrates your ability to contribute to problem-solving efforts and drive continuous improvement.

Teamwork Skills

To effectively contribute to problem-solving efforts and drive continuous improvement as a Six Sigma Yellow Belt, it’s crucial to possess strong teamwork skills.

As a member of a Six Sigma team, your ability to work collaboratively with others is essential in achieving the goals of the project. Effective communication, active listening, and empathy are key skills that will enable you to effectively work with your team members.

Being able to understand and appreciate different perspectives will help in identifying and addressing potential issues more efficiently. Having strong interpersonal skills will foster a positive and productive team environment.

Through yellow belt training, you’ll learn the importance of teamwork and how to leverage the skills of each team member to achieve optimal results. Remember, success in Six Sigma projects heavily relies on the collective effort of the team.

Communication Skills

Strong communication skills are essential for a Six Sigma Yellow Belt to effectively collaborate with team members and drive successful project outcomes. As a certified Lean Six Sigma Yellow Belt, you must be able to communicate clearly and concisely with stakeholders at all levels of the organization, including the tour cast.

This includes actively listening to understand their needs and concerns, as well as articulating your ideas and recommendations in a way that’s easily understood. Effective communication is crucial for gathering and analyzing data, presenting findings, and implementing improvement initiatives.

It also helps build trust and rapport with team members, enabling you to work together more efficiently and effectively. By honing your communication skills, you’ll be better equipped to facilitate productive discussions, resolve conflicts, and ensure that everyone is aligned and working towards the same goals.

Tools and Techniques Used by Six Sigma Yellow Belt

You’ll be introduced to various Six Sigma tools that will help you analyze and improve processes.

One such tool is the Pareto chart, which helps you identify the most significant issues.

You’ll also learn how to use cause and effect diagrams to understand the root causes of problems, as well as how to apply control charts to monitor process performance.

Introduction to Six Sigma Tools

You can effectively utilize a range of tools and techniques as a Six Sigma Yellow Belt to improve processes and drive quality. These tools are designed to help you identify and eliminate defects, reduce variability, and optimize performance.

Some commonly used Six Sigma tools include:

Process maps: These help you understand the flow of a process and identify potential areas for improvement.

Cause and effect diagrams: Also known as fishbone diagrams, these help you identify the root causes of a problem.

Pareto charts: These help you prioritize the most significant issues based on their frequency or impact.

Histograms: These provide a visual representation of data distribution.

Control charts: These help you monitor and control process performance over time. Scatter plots: These are used to identify relationships between variables.

Use of Pareto Charts

To effectively utilize Six Sigma tools and techniques as a Yellow Belt, you can employ Pareto charts.

Pareto charts are a useful tool for identifying and prioritizing the most significant issues in a process. By visually representing data in a bar graph, Pareto charts allow you to see which issues have the greatest impact on the overall outcome. This helps you focus your efforts on addressing the most critical problems first.

As part of your Six Sigma Yellow Belt training, learning how to create and interpret Pareto charts is essential. It enables you to make informed decisions and allocate resources effectively.

Understanding of Cause and Effect Diagrams

One effective way to enhance your understanding of cause and effect diagrams, a tool used by Six Sigma Yellow Belts, is by frequently practicing their creation and interpretation.

Cause and effect diagrams, also known as fishbone diagrams or Ishikawa diagrams, are visual tools that help identify the root causes of a problem or an effect. They’re structured in the form of a fishbone, with the effect or problem at the head and the potential causes branching out from the spine.

By using cause and effect diagrams, Six Sigma Yellow Belts can systematically analyze and identify the various factors contributing to a problem, enabling them to develop effective solutions. These diagrams provide a visual representation of the cause and effect relationships, allowing for a better understanding of the underlying issues.

Through practice and interpretation of cause and effect diagrams, Six Sigma Yellow Belts can effectively apply this tool to improve processes and reduce defects.

Application of Control Charts

Enhancing your understanding of cause and effect diagrams can also be achieved through the application of control charts, a valuable tool and technique used by Six Sigma Yellow Belts. Control charts provide a visual representation of data over time, allowing you to identify and analyze variations in a process.

Here are four ways in which control charts can be applied:

- Monitor process performance: Control charts help you track and measure the performance of a process, enabling you to identify any deviations from the desired target or standard.

- Detect and analyze special causes: By plotting data points on a control chart, you can easily identify special causes of variation, such as equipment malfunctions or operator errors, which can be investigated and addressed.

- Establish process stability: Control charts enable you to determine whether a process is stable or unstable. A stable process exhibits only random variations, while an unstable process shows non-random patterns that require corrective action.

- Improve decision-making: Control charts provide objective data that can support data-driven decision-making. By analyzing the data on the control chart, you can make informed decisions on process improvements and problem-solving.

Control charts can be particularly useful in monitoring the performance of cast albums chart, providing insights into trends and fluctuations in sales and popularity over time within the entertainment industry.

Real-World Applications of Six Sigma Yellow Belt

The successful completion of a Six Sigma Yellow Belt course equips individuals with the basic knowledge necessary to serve as core team members on smaller process improvement projects within their organizations. This foundational sigma certification, often pursued through self-paced online training, is a critical first step for professionals aiming to deepen their understanding of sigma fundamentals, including statistical process control and the DMAIC methodology.

Yellow Belts are enabled to identify processes that could benefit from improvement, understand certification requirements, and participate actively in Sigma teams.

Sigma certifications, including the yellow belt, empower professionals to complete projects that significantly enhance operational efficiency successfully. As a certification that requires participation in online training and passing a series of exams, the yellow belt designation is extremely helpful for those looking to contribute as a core team member on Sigma teams or even lead projects on a smaller scale.

This professional designation, emphasizing sigma roles and sigma process knowledge, enables yellow belts to apply sigma fundamentals and statistical process control in a way that is directly relevant to their work environment, making the yellow belt participants an invaluable asset in any sigma industry.

Role of Yellow Belt in Different Industries

Yellow Belts play a vital role in implementing Six Sigma methodologies and driving process improvement in various industries.

As a Yellow Belt, you can contribute to the success of your organization by applying Six Sigma principles to streamline processes, reduce waste, and improve quality.

In the manufacturing industry, you can use your knowledge of Six Sigma to identify and eliminate defects, resulting in improved product reliability and customer satisfaction.

In the healthcare industry, you can help reduce medical errors and improve patient outcomes by implementing Six Sigma methodologies in hospital processes.

In the service industry, you can enhance customer experiences by identifying and addressing process inefficiencies.

Benefits of Implementing Six Sigma Yellow Belt Practices

As a Yellow Belt practitioner, you can directly observe the benefits of implementing Six Sigma methodologies in real-world applications. By applying Six Sigma Yellow Belt practices, organizations can experience numerous advantages.

One of the key benefits is improved process efficiency. Through the use of tools and techniques like process mapping and data analysis, Yellow Belt practitioners can identify and eliminate waste and inefficiencies in processes, leading to increased productivity and cost savings.

Another benefit is enhanced quality control. By implementing Six Sigma practices, organizations can standardize processes, reduce defects, and improve overall product or service quality.

Implementing Six Sigma can lead to better customer satisfaction. By focusing on customer requirements and reducing variability in processes, organizations can deliver products or services that consistently meet or exceed customer expectations.

Career Opportunities for Six Sigma Yellow Belt Certified Professionals

With this certification, you can explore job roles such as process improvement specialist, quality assurance analyst, or operations analyst.

Not only can you expect competitive salary packages, but you can also look forward to future growth prospects in industries like manufacturing, healthcare, and finance.

Job Roles for Yellow Belt Certified Professionals

Obtaining a Six Sigma Yellow Belt certificate opens up various career opportunities for individuals.

As a Yellow Belt certified professional, you can work as a Process Analyst, responsible for identifying and analyzing process improvement opportunities within an organization. You could also become a Quality Assurance Analyst, ensuring that products or services meet the required quality standards, whether it’s in manufacturing, musical theater productions, or original Broadway cast recording.

Another option is to work as a Data Analyst, gathering and analyzing data to identify trends and patterns for process improvement. You can pursue a career as a Project Coordinator, assisting in the planning, organizing, and implementing of improvement projects, whether in the corporate world or in the management of projects for pop stars tours.

With a Six Sigma Yellow Belt certification, you have the skills and knowledge to contribute to the success of organizations in various job roles, spanning industries from manufacturing to musical theater and beyond.

Salary Expectations

As a Six Sigma Yellow Belt certified professional, you can expect competitive salary packages. The salary expectations for individuals with this certification vary based on factors such as industry, job role, experience, and location.

In general, Six Sigma Yellow Belt certified professionals can earn an average annual salary of $60,000 to $85,000. It’s important to note that these figures are contextually relevant and can vary significantly.

Professionals working in industries such as manufacturing, healthcare, and finance tend to earn higher salaries compared to other sectors. Individuals with more experience and expertise in Six Sigma methodologies may command higher salaries.

It’s essential to research and consider these factors when setting salary expectations as a Six Sigma Yellow Belt certified professional. Winning a Tony Award for best original project on Broadway theatre at the Lena Horne Theatre can also positively impact salary negotiations and career advancement opportunities.

Future Growth Prospects

As a Six Sigma Yellow Belt certified professional, you can explore numerous career opportunities for future growth in various industries and job roles. With your expertise in the principles and methodologies of Lean Six Sigma, you can contribute to process improvement and quality management in organizations.

Many industries, such as manufacturing, healthcare, finance, and information technology, value the skills and knowledge of Six Sigma professionals. As a Yellow Belt, you can start your career as a process improvement specialist, quality analyst, or project coordinator.

With experience and further certifications, you can progress to roles such as Six Sigma Green Belt or Six Sigma Black Belt, leading larger improvement projects and teams. You can also pursue managerial roles, where your Six Sigma background will be highly valued in driving organizational efficiency and profitability.

If you’re interested in entertainment or arts management, your skills in process improvement and quality management can be applied to fields such as Broadway musicals production or managing events. Your expertise could also be valuable in industries like award ceremonies, including the Outer Critics Circle Awards, where efficiency and quality are essential for success.

The future growth prospects for Six Sigma Yellow Belt certified professionals are promising, providing you with opportunities to make a significant impact in your chosen field.

Tips to Pass the Six Sigma Yellow Belt Certification Exam

If you want to pass the Six Sigma Yellow Belt Certification Exam, there are a few key points you need to keep in mind.

First, make sure to create a study schedule and stick to it, focusing on the core concepts and tools of Six Sigma.

Take advantage of exam preparation resources, such as practice exams and study guides, to familiarize yourself with the format and content of the exam.

Study Tips

To excel in the Six Sigma Yellow Belt Certification Exam, you must study with a clear plan and focus on the key concepts. Here are some study tips to help you prepare effectively for the exam.

First, familiarize yourself with the Six Sigma Yellow Belt methodology and its core principles. Understand the contextually relevant tools and techniques used in process improvement.

Next, create a study schedule to allocate enough time for each topic. Break down the content into manageable chunks and review regularly to reinforce your understanding.

Use practice exams and sample questions to test your knowledge and identify improvement areas.

Finally, collaborate with fellow students or join study groups to discuss concepts and share insights.

Exam Preparation Resources

To ensure success in your certification journey, it’s important to have access to reliable study materials and tools. Online platforms such as Udemy and Coursera offer comprehensive courses designed for the Six Sigma Yellow Belt exam.

These courses provide in-depth explanations of the key concepts, case studies, and practice exams to enhance your understanding and test-taking abilities.

Textbooks like ‘The Six Sigma Handbook’ by Thomas Pyzdek and ‘Lean Six Sigma Yellow Belt’ by Bill Wortman can be valuable resources to supplement your learning.

Practice exams and sample questions on websites like ASQ and GoSkills can help you gauge your preparedness and identify knowledge gaps.

Your Six Sigma Yellow Belt certification can also be beneficial if you’re interested in industries involving original scores, such as film or television production. It can assist in optimizing processes related to production workflows, ensuring efficiency and quality in delivering original scores for various media projects.

Importance of Practice Tests

Take practice tests to increase your chances of passing the Six Sigma Yellow Belt Certification Exam.

Practicing with mock exams is an effective way to familiarize yourself with the format and types of questions that may appear on the test. By doing so, you can identify your strengths and weaknesses and focus your study efforts accordingly.

These practice tests also help you gauge your understanding of lean six sigma concepts and techniques, enabling you to identify areas requiring more attention.

Practice tests allow you to simulate exam conditions, helping you manage your time effectively and build your confidence.

Frequently Asked Questions (FAQs)

What Is the History of Six Sigma, and How Has It Evolved Over Time?

The history and evolution of Six Sigma is fascinating. It has transformed over time, becoming a powerful methodology for improving processes and reducing defects. Let’s dive in and explore its journey.

Are There Any Prerequisites or Prior Experience Required to Become a Six Sigma Yellow Belt?

To become a Six Sigma Yellow Belt, you don’t need any prerequisites or prior experience. This level of certification is designed for beginners so you can start learning and developing your skills immediately.

Are There Any Limitations or Constraints to Implementing Six Sigma in Certain Industries or Organizations?

Implementing Six Sigma in certain industries or organizations may have limitations or constraints. Factors such as organizational culture, resistance to change, or lack of resources can impact successful implementation.

How Long Does It Typically Take to Complete the Six Sigma Yellow Belt Certification Process?

Typically, it takes around 2-3 months to complete the Six Sigma Yellow Belt certification process. The duration may vary based on your availability, dedication, and the specific training program you choose.

Can Individuals With a Six Sigma Yellow Belt Certification Pursue Further Levels of Certification, Such as Green Belt or Black Belt?

Yes, individuals with a Six Sigma Yellow Belt certification can pursue further levels of certification, such as Green Belt or Black Belt. This allows you to expand your knowledge and skills in process improvement.