When it comes to quality management, control limits are crucial for maintaining process stability. By establishing these boundaries, you can effectively identify variations that might indicate potential issues. It's not just about knowing when something's off; it's about fostering a culture of continuous improvement in your organization. But how do you calculate these limits, and what types should you consider? Understanding this can significantly impact your overall product quality.

Understanding Control Limits

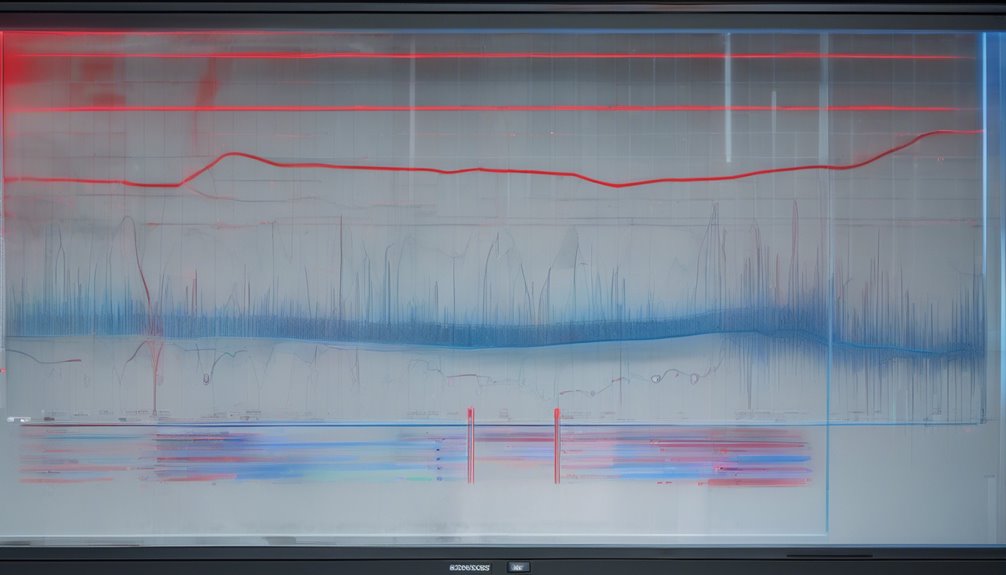

Control limits are essential tools in quality control that help you monitor processes and identify variations. By setting upper and lower limits, you can determine whether a process is stable or if it's exhibiting unusual behavior.

Understanding these limits allows you to distinguish between common cause variations, which are inherent to the process, and special cause variations, which indicate a problem that needs attention.

You'll find that control limits are based on statistical methods, ensuring that your decisions are data-driven. When you regularly review these limits, you can maintain process consistency and improve product quality.

In short, grasping the concept of control limits empowers you to make informed decisions and enhance operational efficiency.

Calculating Control Limits

To calculate control limits effectively, you'll need to gather data from your process and apply statistical methods.

Start by collecting a sufficient sample size of measurements—typically at least 20 to 30 samples. Next, compute the average (mean) and standard deviation of your data.

Using these values, you can establish the upper and lower control limits. The upper control limit (UCL) is calculated as the mean plus three times the standard deviation, while the lower control limit (LCL) is the mean minus three times the standard deviation.

This approach helps you identify variations in your process. Remember, control limits should reflect the inherent variability of your process, so ensure your data is representative for accurate results.

Types of Control Limits

While understanding control limits is crucial for process management, it's equally important to recognize the different types available. The most common types are upper control limits (UCL) and lower control limits (LCL). UCL indicates the maximum acceptable variation in your process, while LCL shows the minimum.

You might also encounter process capability limits, which reflect the inherent variation of a process and help assess its performance. Additionally, you may use specification limits, which define the acceptable range of product characteristics.

Understanding these types will help you effectively monitor and control your processes. By identifying which limits to apply, you can better manage variations and maintain quality standards throughout your operations.

Importance of Control Limits in Quality Management

Understanding the different types of control limits lays the groundwork for recognizing their importance in quality management. Control limits help you monitor process performance and maintain consistency, ensuring that your products meet quality standards.

By setting these limits, you identify variations that may indicate potential problems, allowing you to address them proactively. This leads to reduced waste and improved efficiency.

Control limits also enhance decision-making, giving you a clear framework to assess process stability and capability. They foster a culture of continuous improvement, encouraging your team to strive for excellence. Additionally, the application of statistical process control (SPC) enables you to track and improve process performance effectively.

Ultimately, understanding and applying control limits empowers you to achieve higher quality outcomes, satisfy customer expectations, and strengthen your organization's reputation in the market.

Implementing Control Limits in Your Organization

Implementing control limits in your organization requires a strategic approach that aligns with your specific processes and goals.

Start by identifying critical processes where quality consistency is vital. Gather historical data to establish baseline performance metrics, then calculate the upper and lower control limits based on this data.

Make sure to involve your team in understanding these limits, as their buy-in is essential for success. Regularly monitor your processes against these limits to detect variations early.

When you notice deviations, investigate the root causes and take corrective actions promptly. Finally, continuously review and adjust your control limits as necessary to reflect changes in processes or standards.

This proactive approach will lead to sustained quality improvement and operational efficiency.

Conclusion

Incorporating control limits into your quality management practices is crucial for maintaining process stability and improving product quality. By understanding how to calculate and implement these limits, you can effectively distinguish between normal variations and potential issues. Remember, regular reviews and adjustments are key to keeping your processes efficient. Embracing control limits not only guides your decision-making but also fosters a culture of continuous improvement within your organization. Start prioritizing control limits today for better results tomorrow!