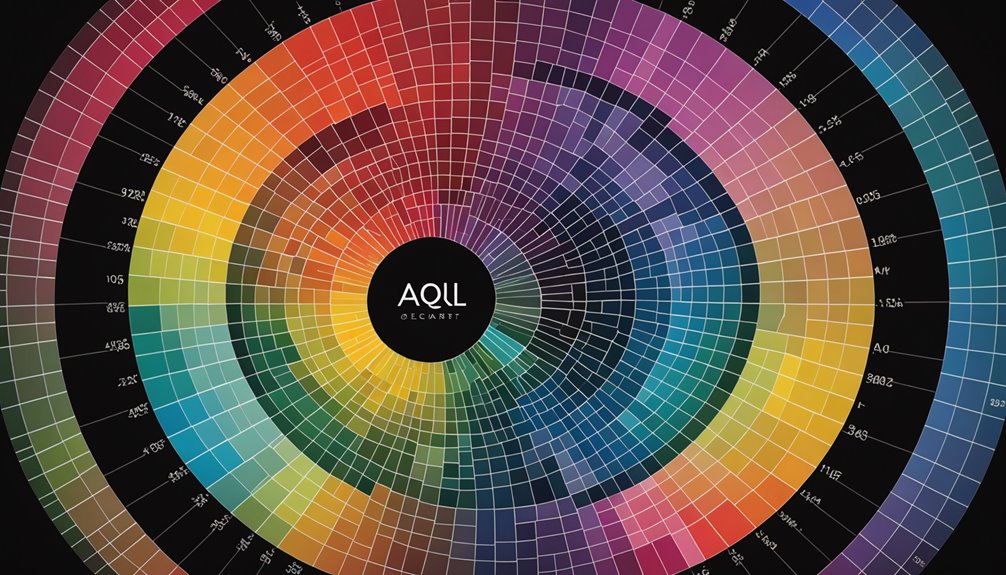

When it comes to maintaining high product standards, the AQL Chart is a tool you can't overlook. It helps you determine how many defects are acceptable in a batch, balancing quality with cost. Understanding how this chart works is crucial for effective quality control. But what happens if you don't implement it correctly? Let's explore the intricacies of the AQL Chart and its impact on your production process.

Understanding the Aql Chart

When you dive into the AQL chart, you'll quickly realize it's a vital tool for quality control in manufacturing and inspection processes.

This chart helps you determine acceptable quality levels, guiding you in deciding how many faulty items you can tolerate in a batch. It's based on statistical sampling, which means you won't need to inspect every single item. Instead, you'll select a representative sample, making the process efficient and manageable.

The AQL chart provides different acceptance standards, depending on the type of product and industry requirements. By understanding the AQL chart, you can effectively balance quality and cost, ensuring your products meet customer expectations while minimizing waste and inefficiencies in your production line.

Importance of Quality Control

Quality control is crucial for any business aiming to maintain a competitive edge and meet customer satisfaction. By implementing effective quality control measures, you ensure that products meet established standards, reducing defects and returns. This not only saves costs but also strengthens your brand's reputation. Customers are more likely to remain loyal if they consistently receive high-quality products.

Moreover, quality control helps you identify areas for improvement, driving innovation and efficiency. When you actively monitor processes and outcomes, you can make informed decisions that enhance productivity. Additionally, incorporating data-driven decision-making into your quality control processes can lead to more precise improvements and higher overall performance.

In the long run, prioritizing quality control leads to increased profitability and market share. By focusing on quality, you build trust with your customers and create a solid foundation for sustainable growth.

How the Aql Chart Works

The AQL (Acceptable Quality Level) chart plays a vital role in quality control by helping businesses determine the maximum number of defects acceptable in a batch of products.

To use the chart, you first decide on your sample size based on the total batch quantity. Then, you select the AQL percentage that aligns with your quality standards.

Next, you'll refer to the chart to find the corresponding acceptance number, which indicates how many defects are tolerable. If your sample has defects equal to or fewer than this number, you can accept the batch; if not, you'll need to reject it.

This systematic approach ensures you maintain quality while minimizing waste and dissatisfaction among customers.

Different Types of Aql Levels

Understanding the different types of AQL levels is key to effectively applying the AQL chart in your quality control processes.

There are three primary AQL levels: the acceptable quality level, the tight AQL, and the loose AQL. The acceptable quality level is typically used for most production, balancing risk and cost.

The tight AQL is ideal for high-stakes products where defects can lead to significant issues, requiring stricter quality control.

Conversely, the loose AQL is suitable for less critical items, allowing for a higher defect rate.

Implementing the Aql Chart in Production

When you implement the AQL chart in production, it's crucial to start by defining your inspection criteria based on the chosen AQL level. This ensures that everyone on your team understands what's acceptable and what isn't.

Next, train your staff on how to use the AQL chart effectively, emphasizing the importance of consistency in inspections.

After that, establish a sampling plan that aligns with your production volume and the AQL level you've selected.

Regularly review the inspection results and adjust your processes as necessary.

Communication is key; keep all stakeholders informed about inspection outcomes and any potential issues.

Finally, ensure you document everything for traceability and continuous improvement.

This structured approach will help maintain quality standards in your production line.

Benefits of Using the Aql Chart

Utilizing the AQL chart can significantly enhance your quality control process, as it provides a clear framework for determining acceptable quality levels. By using this tool, you'll streamline inspections and reduce the time spent on quality assessments. It helps you identify defects quickly, ensuring that only products meeting your standards reach the market.

You'll also find that implementing the AQL chart fosters better communication among team members, as everyone understands the quality expectations. This consistency leads to fewer misunderstandings and higher overall product quality.

Plus, it allows for more efficient resource allocation, as you can focus on areas needing improvement. Ultimately, adopting the AQL chart can lead to increased customer satisfaction and a stronger reputation for your brand.

Common Mistakes to Avoid With Aql Sampling

While adopting AQL sampling can streamline your quality control process, there are common mistakes that can undermine its effectiveness.

One mistake isn't understanding the sampling plan; make sure you know the difference between single, double, and multiple sampling plans.

Another pitfall is failing to define your acceptance criteria clearly, which can lead to confusion during inspections.

Also, avoid sampling too few units, as this won't give you a true representation of the batch quality.

Lastly, don't ignore the importance of training your team on AQL principles; proper knowledge ensures consistency in application.

Conclusion

Incorporating the AQL Chart into your quality control processes is a smart move for any manufacturer. By understanding its workings and implementing it effectively, you can strike the right balance between quality and cost. Remember to avoid common pitfalls, and you'll enhance your product's reliability and customer satisfaction. With a solid grasp of AQL levels, you're well on your way to minimizing waste and boosting your competitive edge in the market.